Products for Business

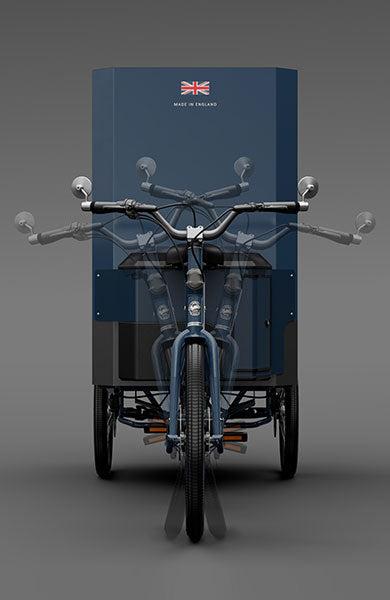

Why won’t just any bicycle do the job? Pashley Carrier Cycles (also known as business bikes, cargo cycles, work bikes, delivery or utility bikes) are designed and built specifically for commercial and industrial use, to carry people and loads safely and efficiently throughout the working day.

They are of robust construction and are equipped to meet the demands that may be placed on them. Loads are securely retained, and the cycles are designed to have stable handling whether fully loaded or empty. They are comfortable to ride and have good stopping power in all weather conditions, and they do their job day in, day out, for many years of service.

For Business

Cargo Delivery

'Last mile' delivery of cargo including post, parcels and pizzas!

View products

For Business

Cycle Fleets

Includes cycle fleets for hotels, employee transport for work and fitness, and hire cycles for tourism.

View Products

For Business

Site Transport

Moving employees, goods and equipment on sites including warehouses, exhibition centres, oil refineries and airports.

View products

For Business

Promotion

Cycles used as a promotional tool for display, events, competitions and advertising.

View Products

For Business

Vending

Portable platform for vending of goods including ice cream, hot and cold drinks, food and newspapers.

View productsServing industry since 1926

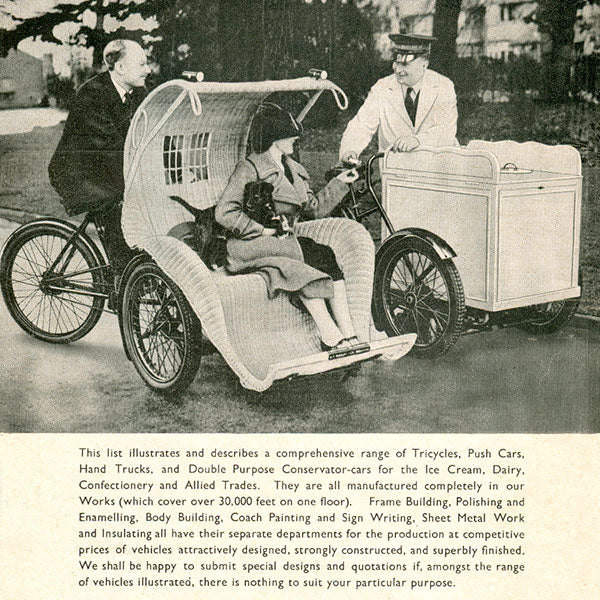

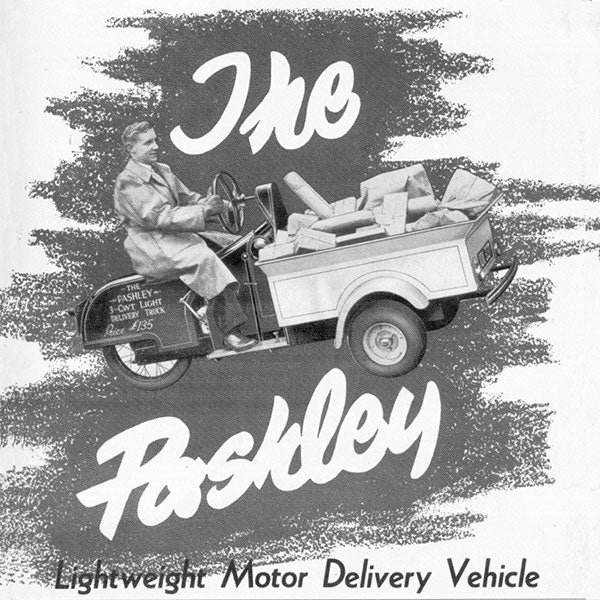

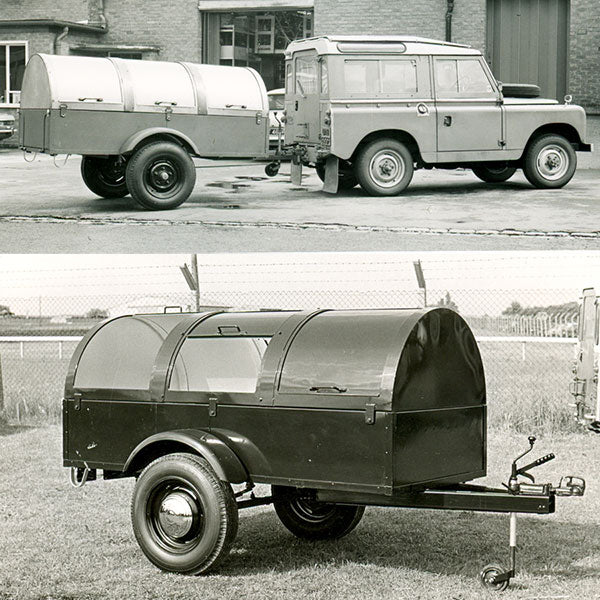

Pashley has been producing cycles for commercial use since the 1920s. Over the years it has produced a huge variety of products including wicker tricycle rickshaws, mobile advertising bikes, dairyman's milk bottle bicycles, and motorised cargo trikes.

Our customers

Our Heritage

Our Expertise

Since 1926

Pashley has become a world-leading manufacturer of cycles for industrial and commerical use, serving industry for over 95 years.

Sold Worldwide

We have over 100 product variants that are sold to commerical customers in over 40 countires around the world.

Loyal Service

We have been a supplier to many businesses, including The Royal Mail, for over 35 years providing product design, spares support and technical training.

Product Design

Our expert team of product designers and engineers innovative new products for a huge variety of business needs, from cargo trikes to fleet cycles for hotels.